Crude oil sampling system automatic sampler Working principle

Sampling head design: The sampling head is the basis of an automated sampling system that is specially designed to ensure efficient sample extraction from the reservoir or pipeline at any pressure and temperature. Inside the sampling head are multiple small holes whose size and shape are precisely designed to ensure uniform sampling and reduce contamination of the crude oil.

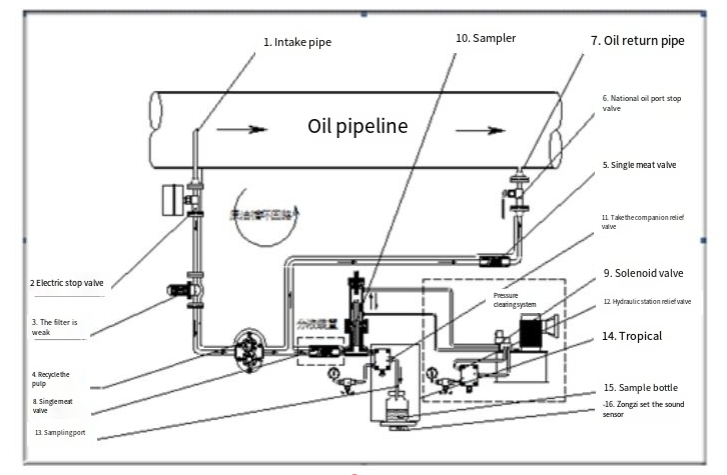

Circulation loop: The crude oil flows in the circulation loop composed of sampling probe, manual ball valve and filter under the action of variable frequency circulation pump. The loop is designed so that the inlet flow rate is equal to the flow rate of the crude oil in the pipeline, thus ensuring representative sampling.

Separation and collection: The separator draws the right amount of crude oil in the circulation loop, and the amount of separation can be controlled by the meter electronic signal or the electronic clock signal. The collected samples are stored in a closed, variable volume receiver with the same pressure and similar temperature as in the pipe, further ensuring sample representativeness.

Water cut test and data recording:Custom sampling system At the same time of automatic sampling, the water cut test transmitter will synchronously detect the water cut value of the crude oil in the circulation loop and input the data into the computer in real time. The built-in data management system records and stores all sample information, including sample origin, collection and test results.

HCYZ series crude oil automatic sampler for crude oil (pipeline transportation, shipping, truck handling) sampling field actual situation, in accordance with ISO3171, SY/T5317-2006 two standards designed and manufactured. It is widely used for sample collection of crude oil pipeline transportation, shipping, truck loading and unloading, especially in line with the requirements of accurate measurement at the trade interface;

The crude oil automatic sampler designed and produced by our company takes time and flow ratio samples; And can implement

communication remote transmission control. Multiple crude oil pipelines can also be automatically sampled.

The design of the sampler conforms to the standard Q/320323TEB01-2010, SY5317-2006 "Crude Oil Pipeline Automatic Sampling

Method" and the international standard ISO3171.

HCYZ-II-W Crude Oil pipeline automatic sampler Features:

Use time proportional sampling and flow proportional sampling two working modes. It has the functions of automatic alarm,

automatic heat tracing, anti-overflow of sample bottle and so on.

Variable positive displacement sample receiver can ensure that the pressure and temperature in the pipeline are consistent

to ensure the representative sampling.

The linear velocity of the liquid entering the sampling probe is equal to the linear velocity of the liquid flowing through the

probe in the main line.

The control core of the sampler is Siemens S7-smart series programmable logic controller (PLC), the man-machine interface

adopts Siemens IE700 series touch screen, and the components are imported high-quality products to ensure the safe use of

products and stable performance.

Technical parameter

1, appearance size: about 660X 660X 1200 (mm), stainless steel shell, and according to user requirements design;

2, power input: a. Voltage: 380V±10%; b. Power: 4.0kW (4*1.5 flame retardant cable can be used)

3, motor power: 0.75kW, 0.37kW;

4, working medium: temperature: 80℃ below; Viscosity: fluidity;

5, pressure: below 4.0Mpa (higher than 4.0Mpa separately designed);

6, the working environment: depending on the freezing point of the medium, below the freezing point should be

insulated or electric heat tracing;

7, performance coefficient: 0.95-- 1.05 (better than the international standard of 0.90 -- 1.10);

8, sampling interval time/flow (cycle) : interval time 10-- 999 (s) adjustable, interval flow is adjustable;

9, single sampling amount: 1.5-10 (ml) (adjustable), and can be designed according to user needs;

A sampling system usually refers to a system that can intermittently (or discretely) sample a continuous signal and convert it into a discrete signal (such as a pulse train or a digital sequence) for subsequent processing or storage.Custom sampling system At the heart of this process is the sampling technique, which obtains a series of discrete signal values by measuring a continuous signal at a specific point in time (sampling point).

A sampling system usually refers to a system that can intermittently (or discretely) sample a continuous signal and convert it into a discrete signal (such as a pulse train or a digital sequence) for subsequent processing or storage.Custom sampling system At the heart of this process is the sampling technique, which obtains a series of discrete signal values by measuring a continuous signal at a specific point in time (sampling point).

A sampling system usually refers to a system that can intermittently (or discretely) sample a continuous signal and convert it into a discrete signal (such as a pulse train or a digital sequence) for subsequent processing or storage.Custom sampling system At the heart of this process is the sampling technique, which obtains a series of discrete signal values by measuring a continuous signal at a specific point in time (sampling point).